Trucks are robust machines designed to withstand heavy usage and adverse conditions. However, like any mechanical device, they are prone to various issues that can interfere with their performance or even lead to breakdowns. This article will explore common truck problems and provide tips on how to avoid them. Understanding these truck problems can help you maintain your vehicle in top-notch condition and save you from costly repairs.

Engine Overheating

Engine overheating is a common issue in the trucking industry. It is often caused by low coolant levels, a faulty thermostat, or a damaged radiator.

Regular checks and maintenance are crucial to prevent this problem. Ensure that the coolant level is adequate and the cooling system is functioning correctly.

If the thermostat or radiator shows any signs of damage, it is advisable to replace them to prevent further complications and ensure the smooth operation of the engine. Taking these preventive measures can save time, money, and potential breakdowns on the road.

Starter Failure

A failing starter can be a major inconvenience for your transport truck, rendering it immobile and causing frustration. Common symptoms of a failing starter include a grinding noise when starting the truck or the engine not turning over.

To avoid such issues, it is crucial to regularly inspect the starter and its components, and replace them promptly. By taking these preventive measures, you can significantly reduce the chances of starter failure and ensure the smooth operation of your truck.

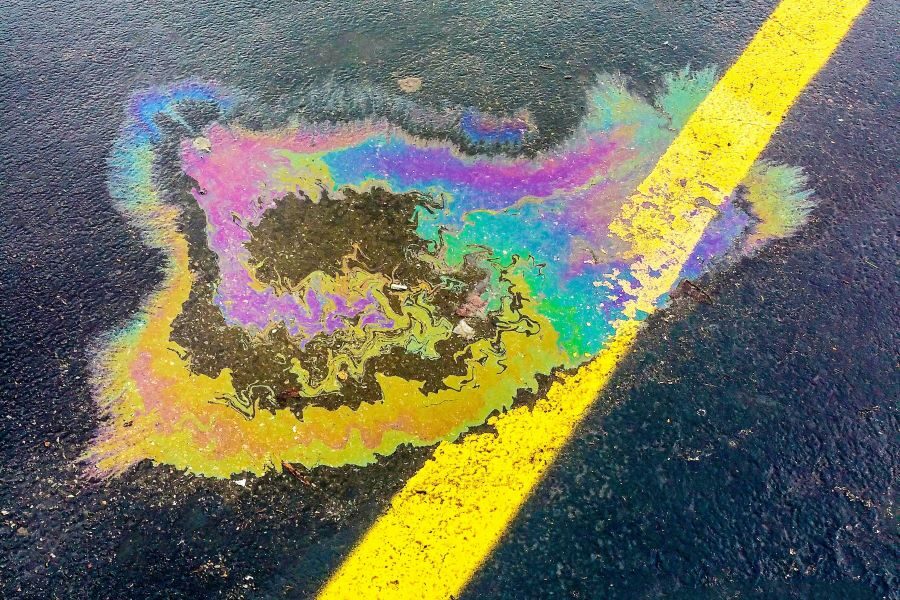

Oil Leaks

Truck breakdowns are often the result of oil leaks, which, if not promptly addressed, can lead to significant engine damage. Without enough oil in the engine, the parts of your fleet vehicle lose lubrication, causing them to rub against each other and lead to early wear and tear.

To avoid this common truck problem, regularly inspect your truck for oil spots and closely monitor oil levels. Taking early action to fix any leaks can help prevent costly engine repairs in the future.

Brake Problems

One of the most dangerous causes of truck breakdowns is the brakes. Failing to recognize this issue can lead to accidents that can cause severe injury or even death. Wear and tear on brake pads, rotors, and calipers are common culprits for brake problems.

To avoid such issues, it is crucial to regularly inspect the brakes and their components, including the hydraulic system. Regular brake inspections and timely replacement of brake pads and rotors can also help prevent most brake-related issues.

Electrical Issues

Modern trucks heavily rely on their electrical systems, which unfortunately makes them susceptible to potential electrical issues. These issues can manifest in various ways, such as problems with the battery, alternator, wiring, or electrical components like lights and power windows.

To diagnose any electrical glitches, a good starting point is to check the battery voltage, and carefully inspect the wiring for any visible damages. You should also perform tests on the electrical components using a multimeter. This proactive approach allows for the detection and timely resolution of any problems before they escalate into major concerns.

Tire Blowouts

Tire blowouts can be highly dangerous, particularly when driving at high speeds. It is crucial to regularly inspect tires for wear and tear, maintain proper tire pressure, and ensure timely tire replacements. By implementing these practices, drivers can significantly reduce the risk of tire blowouts and enhance road safety for themselves and others.

Wheel Bearing Degradation

Degraded wheel bearings in cargo trucks in the Philippines can lead to a rough ride and even wheel detachment in severe cases. This can pose significant risks to both the vehicle and its occupants.

To ensure safety on the roads, it is crucial to regularly check the wheel bearings for signs of wear such as unusual noise or excessive play. If any signs of wear are detected, immediate replacement is necessary to prevent further damage and potential accidents.

U-Joint Failure

The U-joint, also known as the universal joint, plays a critical role in transferring power from the engine to the wheels. When a U-joint starts to fail, it can result in noticeable vibrations and noises during driving.

To avoid such issues, it is important to regularly inspect and lubricate the U-joint. You might also need to replace it if it shows signs of wear to prevent further damage and ensure the smooth operation of your truck. Taking these preventive measures can significantly reduce the risk of U-joint failure and ensure smoother and safer driving experiences.

Transmission Issues

Transmission problems can negatively impact your truck’s performance, and in some cases, it can even leave your vehicle immobile. To prevent this truck problem, it is crucial to conduct regular checks and changes of transmission fluid.

Additionally, timely repairs or replacements of worn-out parts can significantly contribute to avoiding transmission problems. By staying proactive and attentive to your truck’s transmission needs, you can ensure optimal performance and avoid costly breakdowns in the long run.

Fuel System Malfunction

A malfunctioning fuel system can lead to reduced fuel efficiency or engine failure. This issue can greatly affect your truck’s performance and result in costly repairs. Regular commercial truck maintenance and cleaning of the fuel system, along with the replacement of worn-out components, can help prevent fuel system malfunctions.

Keep Your Vehicle Running Smoothly

Prevention is always better than cure, especially when it comes to maintaining your truck. Regular inspections and preventive maintenance can help you avoid the most common truck problems. By understanding these issues and how to prevent them, you can keep your truck running smoothly and efficiently, saving yourself time, money, and stress in the long run.

When you acquire a truck from Prime Quest, you gain access to customized services for your vehicle. Choosing these services allows you to enhance your truck’s operational efficiency.